RockRebar®

Abundant Lava Basalt Rock

A modern Green Tech that’s Naturally Renewable. A Sustainable Alternative to Rusty, Steel Rebar

ROCKREBAR® (BFRP) BASALT FIBER REINFORCED POLYMER RockRebar® is modern tech product that when tested, proved to be only 1/4th the weight of steel, yet proved to have a higher tensile strength than traditional steel rebar. The June 2016 official printing of AC-454 now labels continuous basalt fiber and a special manmade fiberglass known as E-CR (corrosion resistant) fiberglass as sufficiently similar in overall performance as to be interchangeable for use in producing FRP Fiber Reinforced Polymer concrete reinforcements. Brown basalt fiber reinforced polymer aka, BFRP rebar and the white fiberglass rebar aka GFRP are now the only two “glass state” structural fibers officially recognized for concrete reinforcement. Naturally, occurring basalt has several advantages.

RockRebar® aka. (BFRP / Basalt Fiber Reinforced Polymer) rebar is based on one component, NATURALLY renewable lava basalt rock. Abundant lava basalt covers 70% of the earth’s surface. Unlike the manmade recipe for Silica based glass fiber you don’t need toxic chemicals to create Basalt based glass and no contaminated waste is created from its production. Basalt is abundant, cost effective, self-sustainable and eco-friendly. Basalt rock is crushed and loaded into a furnace where it’s melted at extreme temperatures. The molten rock is further processed by being drawn through platinum bushings. As the fibers are drawn, they are stretched taut, decreasing their diameter up to 90 percent and dramatically increasing their strength. Finally, the basalt exits the process as a continuous, “glass-state” fiber, which is referred to as Continuous Basalt Fiber aka. CBF.

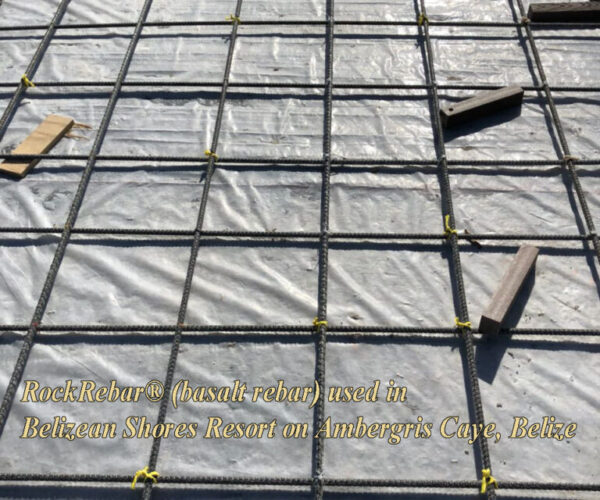

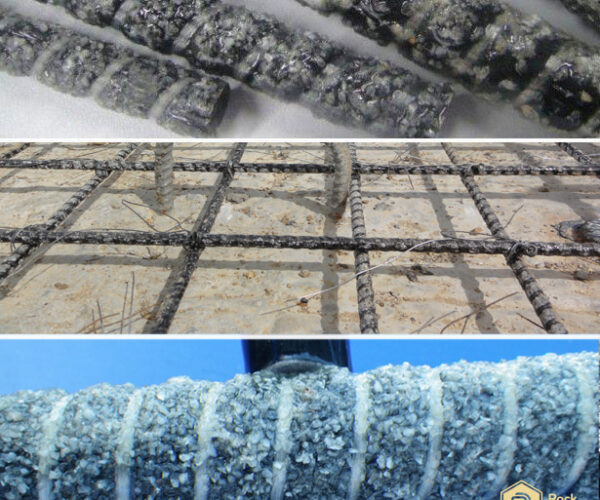

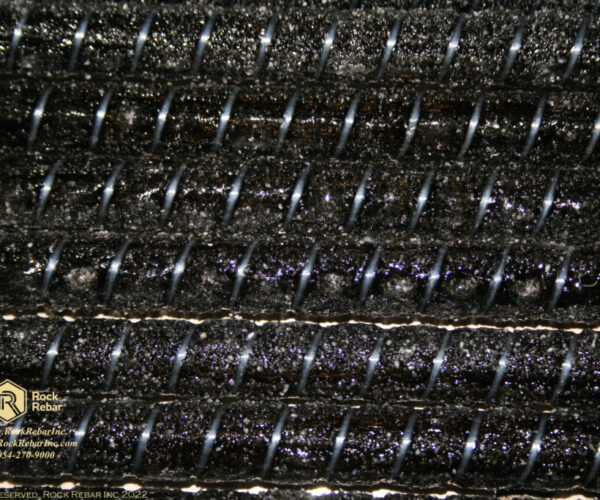

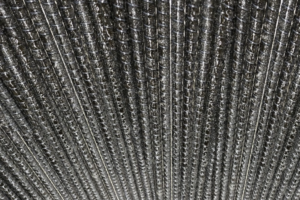

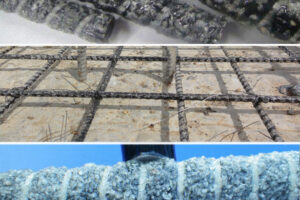

To produce RockRebar® and RockStirrups® we take thousands of continuous strands of CBF and coat them with our proprietary epoxy resin. This tenacious epoxy is the adhesive. Our process is seamless and continuous. The epoxy/ fiber matrix is moving thru a series of dies constantly being stretched and compressed until they form a structural cylinder-type shape that’s 80% CBF and 20% epoxy. Next a Dacron strand is wrapped tightly around the fibers, creating a shape change to ensure concrete will have a mechanical gear lock with it. Then a coating of high compressive strength cracked quartz sand is applied to the bundle further ensuring loads from the concrete are transferred uniformly to RockRebar® in what is termed “local bonding”. A series heating process raises the epoxy fiber matrix temperature to crosslink and cure basalt “rock hard” as industry recognized, innovative replacements for traditional rusty black steel rebar.

RockRebar®, and RockStirrup®, own a lasting piece of concrete rock!

History Of Rockrebar®

What is RockRebar®

A Green, Renewable and Sustainable alternative to rusty steel rebar.

RockRebar® is 80% based on one component, NATURAL volcanic basalt rock. Basalt rock covers 70% of the earth’s surface, and unlike the manmade recipe for white fiberglass. Basalt rock converted into a “glass-state” basalt fiber does not

require toxic chemicals to create it!

No contaminating waste is created from its production.

Structural basalt glass fiber is cost effective, naturally renewable, and Eco-Friendly. In its production, basalt rock is crushed and loaded into a furnace where it’s melted at extreme temperatures. The molten rock is further processed by being drawn through platinum bushings. As the fibers are drawn from the bushings, they are stretched taut, increasing fiber strength as their diameter is reduce up to 90%. A proprietary “size” solidifies each of the continuous, “glass-state” basalt fibers at 17

millionths of a meter as they exit the process at:

More than 250% higher tensile strength than that of Rusty Black Steel!

We take thousands of these continuous strands of Basalt fiber, coat them with our proprietary epoxy resin adhesive and pass this matrix thru a series of compression dies forming a cylinder-type shape. Before the final curing, a Dacron® strand is wrapped tightly around the fibers to cause a “squeezing” resulting in shape changes that will ensure concrete will fill in the deformations forming a mechanical grip to RockRebar®. To further enhance grip with concrete, a coating of resilient crush resistant quartz sand is applied to the bundle as it begins to solidify by heat curing. The final result. RockRebar®, a time tested, industry recognized and totally non-rusting alternative for traditional steel reinforcement.

Why Use RockRebar®

The June 2016 official printing of AC-454 now allows for basalt fiber reinforced polymers (BFRP) to be used in the reinforcement of concrete. Additionally, states are also mandated to consider “life cycle” costs of all future road and bridge products as written in the Moving Ahead for Progress in the 21st Century Act (MAP 21) passed on July 6, 2012.

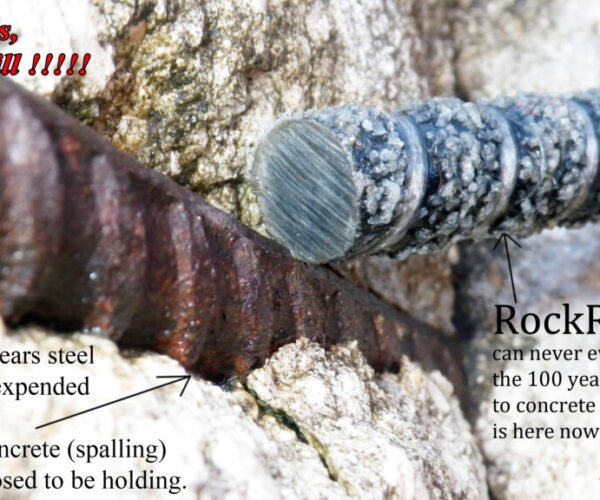

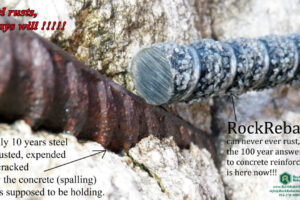

Due to the fact that Basalt products cannot ever rust, we believe RockRebar® will meet the mandated requirements, vastly reducing the need to redo infrastructure and obtain ultra-low maintenance costs over time.

With its durability, strength and longevity, basalt has no true rival; it will no doubt be the last rock standing.

Why RockRebar® is a Superior FRP

RockRebar® ( BFRP / Basalt rebar) is a product that when tested, proved to be only 1/4th the weight of steel, yet proved to have over 250% higher tensile strength than traditional steel rebar. The June 2016 official printing of AC-454 now labels continuous basalt fiber and a special manmade fiberglass E-CR (corrosion resistant) fiberglass as sufficiently similar in overall performance as to be interchangeable for use in producing FRP concrete reinforcements. Brown basalt fiber reinforced polymer BFRP rebar and the white fiberglass GFRP rebar are now the only two “glass state” structural fibers officially recognized for concrete reinforcement. Naturally, occurring basalt has several advantages.

With only a single component required to produce continuous basalt fiber, the quarry process to collect basalt rock requires less of a carbon footprint in comparison to mining a dozen minerals to produce man-made white silica-based E-CR fiberglass. Boron, a potentially toxic trace mineral, is present in white fiberglass. However, at the base fiber level, basalt is non-toxic and naturally boron-free. Basalt rock is naturally boron free and clearly basalt is time proven to remain “rock solid”, standing today when all other minerals have long since eroded away.